STARRETT NEWS & EVENTS

Dialing in your Power X3: How to Choose the Correct Reciprocating Blade

Reciprocating saw blades, also known as “recips”, offer many advantages for efficient cutting. Recips are less labor intensive to use, provide ease of access in many applications, cut faster and more accurately than hand saws and can offer a greater cutting capacity compared to abrasive cutoff wheels. Also, when compared with cutoff wheels, recips have higher levels of safety due to reduced vibration, noise and produce minimal to no sparks. Having a typically “spark-free” process, means there is less risk of operator injury as well as fires.

Designed to cut all types of materials including metal, wood, and plastics in solid and profile form, recips such as the new Starrett 3X POWER Bi-Metal reciprocating blades are designed for numerous industries and applications, including metal fabrication, construction and engineering, and for the dismantling of metal and wood structures/ frameworks. They can also be used in the reclamation industry, pallet dismantling, vehicle repair and dismantling, fire and rescue for emergency extrication, as well as DIY.

How to Identify the Right Blade Some recip blades such as within the 3X POWER range, have shanks that are color coded to enable easy identification of the blades’ cutting capability. Note also that the Starrett 3X POWER Recips feature a universal shank that is designed to fit any corded or cordless machine. The color code on each shank is extremely helpful and offers the following data for selection: -Blue = Metal cutting -Red = Multi-use for the cutting of metal, wood and other types of materials -Yellow = Wood cutting, including hard and soft woods -Black = Heavy duty multi-use - a more robust blade for cutting metal, wood and other types of materials -Grey = Unpainted for pallet dismantling - cutting through wood and nail combination

|  |

Five Straight Forward Steps for Choose the Correct Blade

- Step One: What material are you cutting?

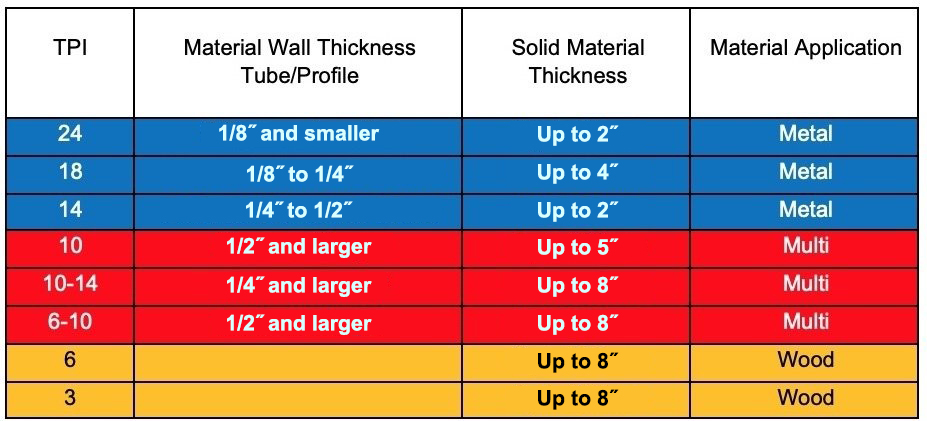

It is always a good idea to consult with your blade supplier for recip selection recommendations, and it can also be helpful to reference the TPI (Teeth Per Inch) chart found under Step Three for some useful guidelines based the material being cut.

Understandably, the material that is being cut has the most influence on which type of recip blade to use. This is especially true when cutting metals, such as aluminum, steel and stainless steel.

For aluminum, it is generally recommended to use a blade with less teeth per inch (TPI) to increase gullet size, increase strokes per minute (SPM) and turn the orbital function on. (This function is explained later.) Aluminum is a “different animal” in that it requires plenty of space in the gullet for swarf and chips to be evacuated and remain cool enough so as not to fuse with the teeth. For steel and stainless, the TPI should abide by the recommendations per material thickness. The general rule of thumb is the thicker the material, the lower the TPI. Also, use a medium SPM and medium feed pressure with the orbital function turned on for improved cutting rates.

For stainless steel, set to low SPM and increased feed pressure with the orbital function turned off. For example, when cutting 2-in. steel tube with a wall thickness of 0.16 in., choose a cutting blade with a blue shank, which is available on the 3X Power recip blades. The same blade type and shank is suitable on an SAE 1020 1/8-in. sheet of metal.

No matter the material type, it is always a good idea to consult with the blade supplier for recommendations. It can also be helpful to reference the TPI chart (shown on next page) for useful guidelines based on the material being cut.

- Step Two: How to Calculate Blade Length

First, measure the dimension/ thickness of the cut section in the material you wish to cut. For Example, 1 - where a 2" (50mm) steel tube is being cut, here is the calculation to follow:

Add 2" (50mm) for blade tip clearance, plus 1" (25mm) for the machine stroke to the cut section. (This additional 3" (75mm) is standard and needs to be added to any cut section)

When added together the result is the minimum blade length required: 5" (125mm).

In summary : 2" (50mm) cut section + 2" (50mm) blade tip clearance + 1" (25mm) machine stroke = a minimum of 5" (125mm) required. This means that the application would require at least a 6” blade, because most recip blades are available in either 4”,6”, 8”, 9” or 12” lengths

For Example 2 , where a SAE 1020 1/8” (3.175mm) sheet is being cut. Following the same formula as provided above, add 2” (50mm) for the stroke and 1” (25mm) for clearance to the cross section of 1/8” (3.175mm). The best recip blade length for this application is a 4” length.

- Step Three: How to Select TPI (Teeth Per Inch)

Equally important, the correct TPI (also referred to as “pitch”) needs to be determined. To help, the easy-to-follow chart below can be used as a reference. For Example 1, see the blue/ metal section for the steel tube and because the wall thickness is .16" (4mm), we can identify the correct TPI is 18.

Note that for a solid material you would want to consider the material thickness to determine the optimal TPI. For a 2" (50mm) solid metal an 18 TPI blade would be needed.

In Example 2, an 1/8” thickness will require a 24 TPI blade to make the cut and provide a fine finish with minimal burr.